Stainless Steel Metal Detector

Product Details:

- Product Type Metal Detector

- Usage For detecting foreign objects.

- Power Supply Electric

- Color Sliver

- Material Stainless Steel

- Waterproof Yes

- Click to View more

Stainless Steel Metal Detector Price

- 1 Unit

- 300000 INR/Unit

Stainless Steel Metal Detector Specification

- Yes

- Stainless Steel

- Sliver

- Electric

- For detecting foreign objects.

- Metal Detector

Stainless Steel Metal Detector Trade Information

- Mumbai

- Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cheque

- 100 Unit Per Month

- 4 Week

- As per requirement

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, All India, Lakshadweep, Tripura, Manipur, Sikkim, Jammu and Kashmir, Meghalaya, Jharkhand, West Bengal, Delhi, Karnataka, Bihar, Chandigarh, Goa, Madhya Pradesh, Maharashtra, South India, East India, Assam, Pondicherry, Haryana, Punjab, Mizoram, Arunachal Pradesh, Tamil Nadu, Rajasthan, Gujarat, Uttar Pradesh, North India, Telangana, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh

- ISO

Product Description

Leveraging on our years of experience, we have been able to manufacture, supply and export premium quality Stainless Steel Metal Detectors made with high class stainless steel. These metal detectors are known for its fine finish, high functional life, optimum performance, precise detection, user-friendly and durability. These Stainless Steel Metal Detectors are highly demanded by our customers and are available in different specifications and as per the client need and demand at market leading prices.

A stainless steel metal detector is a specific gadget used to recognize and distinguish stainless steel items or foreign substances in different applications and businesses. Stainless steel metal detectors are intended to separate stainless steel, a non-ferrous metal, from ferrous metals (like iron) and other non-metallic materials.

Features of Stainless Steel Metal Detector:

- Pneumatic flap

- Diverter arm

- Dual channel operations

- Used for engineering purpose

- Belt retracting

- Air jet

- Belt stop types of reject mechanism

FAQs of Stainless Steel Metal Detector:

Q: For what reason are stainless steel metal detectors significant?

Q: How do stainless steel metal detectors function?

Q: Where are stainless steel metal detectors regularly utilized?

Q: What are a few run-of-the-mill utilization of stainless steel metal detectors in the food business?

Q: Might stainless steel metal detectors at any point identify different kinds of metals other than stainless steel?

Q: How are phony problems limited in stainless steel metal detectors?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

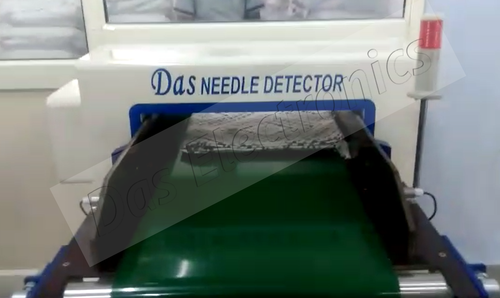

Other Products in 'Metal Detectors' category

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |