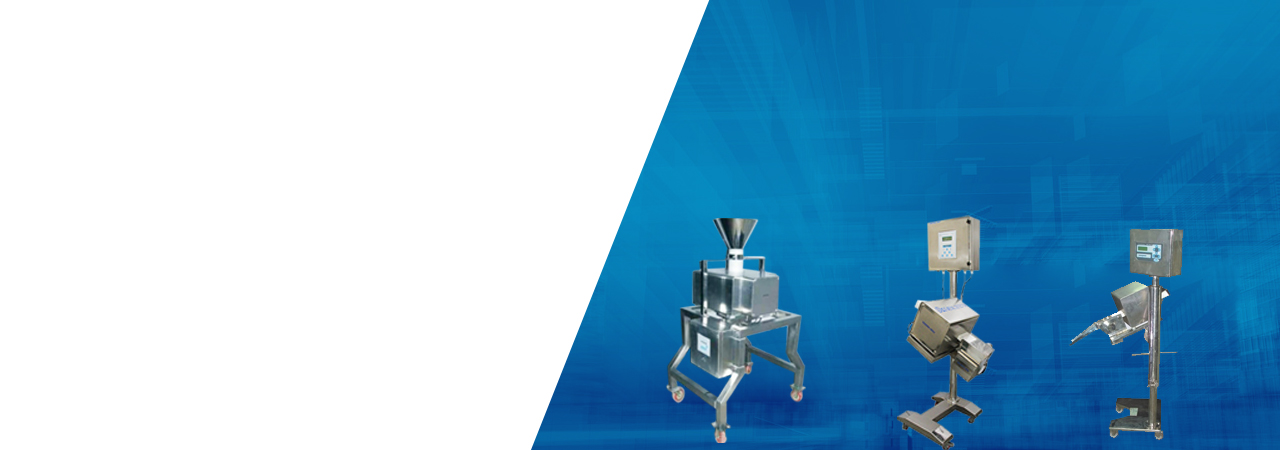

Pharmaceutical Metal Detector

Product Details:

- Frequency 50 Hertz (HZ)

- Usage Industrial

- Alarm ound,Led Lights

- Color Sliver

- Warranty 1 Year

- Power Supply Electric

- Material Stainless Steel

- Click to View more

Pharmaceutical Metal Detector Price and Quantity

- 300000 INR/Unit

- 1 Unit

Pharmaceutical Metal Detector Specification

- Sliver

- ound,Led Lights

- Industrial

- 50 Hertz (HZ)

- Stainless Steel

- Electric

- 1 Year

Pharmaceutical Metal Detector Trade Information

- Mumbai

- 30 Unit Per Month

- 1 Week

- As per requirement

- Chandigarh, Himachal Pradesh, Sikkim, Manipur, Pondicherry, Uttarakhand, Dadra and Nagar Haveli, Lakshadweep, South India, North India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Rajasthan, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Delhi, Gujarat, East India, Andhra Pradesh, Central India, Chhattisgarh, All India

- ISO

Product Description

A pharmaceutical metal detector is particular gear utilized in the pharmaceutical business to distinguish and eliminate metallic pollutants or unfamiliar items in pharmaceutical items. These detectors assume a basic part in guaranteeing the wellbeing and nature of pharmaceutical meds and different items.

Pharmaceutical Metal Detector Features:

- Best sensitivity to all metals

- Stable to vibration and product signal

- Customized and Standard apertures

- Power Fail safe

- Washable reject mechanism available

Specification of Pharmaceutical Metal Detector:

|

Features |

Plugged in Charging |

|

Brand |

Das Electronics |

|

Range |

4 to 6 Meter |

|

Alarm Mode |

Sound |

FAQs of Pharmaceutical Metal Detector:

Q1: What is the motivation behind a pharmaceutical metal detector?

A1: The basic role of a pharmaceutical metal detector is to guarantee the wellbeing and nature of pharmaceutical items by identifying and eliminating metallic impurities or unfamiliar items that might be available during the assembling or bundling process. This forestalls expected damage to patients and keeps up with item respectability.

Q2: How does a pharmaceutical metal detector function?

A2: Pharmaceutical metal detectors regularly work on the rule of electromagnetic enlistment. They discharge an electromagnetic field and dissect the signs got from pharmaceutical items as they go through the field. In the event that a metal impurity is available, it upsets the field, setting off a caution and a dismissal system to eliminate the sullied item from the creation line.

Q3: What kinds of metallic impurities might pharmaceutical metal detectors at any point recognize?

A3: Pharmaceutical metal detectors are intended to identify a great many metallic foreign substances, including ferrous metals (iron and steel), non-ferrous metals (copper, aluminum, and so on), and hardened steel. They can recognize both attractive and non-attractive metals.

Q4: Are pharmaceutical metal detectors delicate to the size of metal pollutants?

A4: Indeed, the awareness of pharmaceutical metal detectors can be acclimated to distinguish metal impurities of various sizes. This permits makers to redo the detector's settings to meet explicit item prerequisites and security principles.

Q5: Might these detectors at any point separate between metal impurities and the metallic parts of the pharmaceutical items themselves?

A5: Present day pharmaceutical metal detectors are intended to recognize metal impurities and the metallic parts of the pharmaceutical items, for example, case shells, tablet coatings, or bundling materials. They utilize progressed programming and sign handling to limit deceptions.

Q6: Are pharmaceutical metal detectors simple to incorporate into pharmaceutical creation lines?

A6: Indeed, pharmaceutical metal detectors are regularly intended to be effortlessly coordinated into pharmaceutical creation lines. They can be introduced at different focuses along the line, like after tablet pressure, embodiment, or bundling processes, to guarantee exhaustive metal recognition. Reconciliation might require some customization in light of explicit creation needs.

Q7: What happens when a metal impurity is identified by the machine?

A7: When a metal toxin is distinguished, the pharmaceutical metal detector sets off a caution and, much of the time, initiates a dismissal system. This instrument can eliminate the tainted item from the creation line, guaranteeing that it doesn't arrive at the last bundling or circulation stage. This keeps up with item security and quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Pharmaceutical Metal Detecting Machines' category

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |