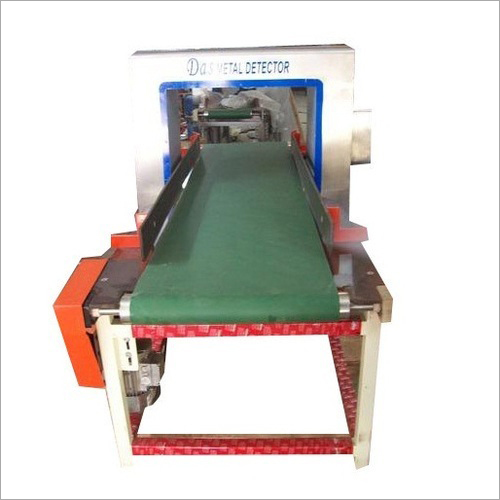

Loose Product Metal Detector

Product Details:

- Power Supply Electric

- Weight 50-100 Kilograms (kg)

- Material Stainless steel,Mild steel

- Warranty 1 Yeas

- Alarm Light

- Product Type Loose Product Metal Detector

- Click to View more

Loose Product Metal Detector Price and Quantity

- 300000 INR/Unit

- 1 Unit

Loose Product Metal Detector Specification

- Electric

- 50-100 Kilograms (kg)

- 1 Yeas

- Stainless steel,Mild steel

- Light

- Loose Product Metal Detector

Loose Product Metal Detector Trade Information

- 30 Unit Per Month

- 4 Week

Product Description

A loose product metal detector, frequently alluded to as a metal discovery framework for loose products, is a specific piece of hardware intended to distinguish and eliminate metal impurities from mass or loose materials during the production or bundling process. These frameworks are ordinarily utilized in different ventures, for example, food handling, drugs, plastics, and reusing, to guarantee product security and quality.

Specifications of Loose Product Metal Detector:

FAQs of Loose Product Metal Detector:

Q1: What are loose product metal detectors utilized for?

A1: Loose product metal detectors are utilized to recognize and eliminate metal impurities, like parts of metal or unfamiliar items, from mass or loose materials. They assist with guaranteeing the immaculateness and wellbeing of products in different businesses.

Q2: How really do loose product metal detectors work?

A2: Loose product metal detectors work on the rule of electromagnetic acceptance. They produce an electromagnetic field and use sensors to identify disturbances in this field brought about by the presence of metal impurities. At the point when metal is recognized, the framework sets off a caution or initiates systems to eliminate the defiled product from the production line.

Q3: What sorts of materials can be investigated with loose product metal detectors?

A3: Loose product metal detectors can be utilized to examine many materials, including mass food products, powders, granules, synthetics, drugs, and recyclable materials.

Q4: What are the outcomes of neglecting to recognize metal foreign substances in loose products?

A4: Neglecting to recognize metal impurities in loose products can have serious results, including mischief to shoppers in the event that the tainted product is ingested or utilized, harm to handling gear, and harm to an organization's standing. Also, it can result in rebelliousness with security and quality guidelines.

Q5: Can loose product metal detectors identify non-metallic foreign substances?

A5: Loose product metal detectors are explicitly intended to distinguish metallic pollutants. They may not be viable at recognizing non-metallic foreign substances, like plastic, glass, or wood. Consequently, other assessment frameworks like X-beam machines or vision frameworks might be utilized related to metal detectors for thorough product examination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Metal Detectors' category

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |