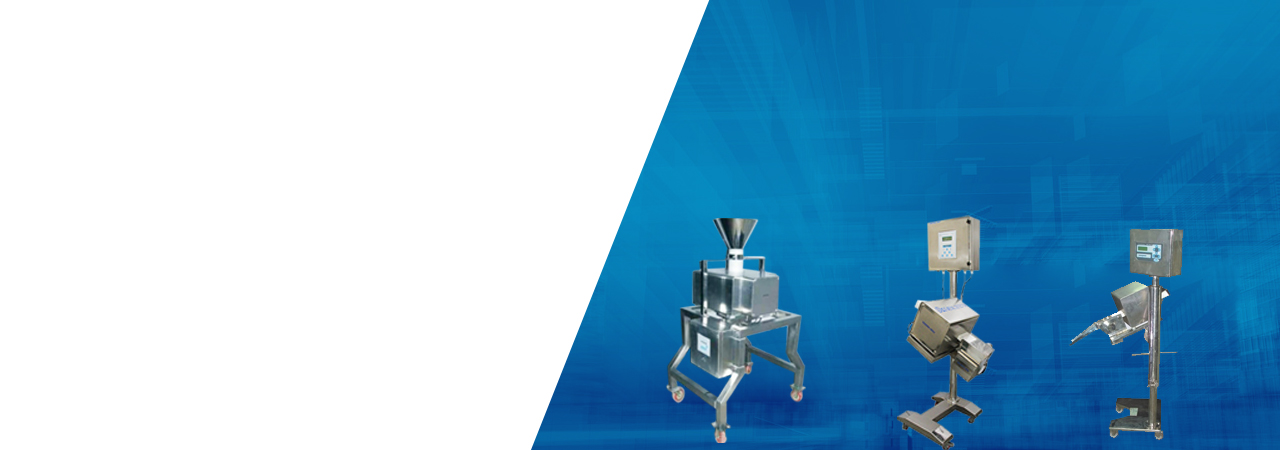

Industrial Wafer Metal Detector

Product Details:

- Color white

- Usage Industrial

- Power Supply Electric

- Product Type Wafer Metal Detector

- Material Stainless Steel

- Click to View more

Industrial Wafer Metal Detector Price and Quantity

- 1 , , Unit

- 300000 INR/Unit

Industrial Wafer Metal Detector Specification

- Stainless Steel

- Industrial

- Wafer Metal Detector

- Electric

- white

Industrial Wafer Metal Detector Trade Information

- 30 , , Unit Per Month

- 4 Week

Product Description

Detection range of this Industrial Wafer Metal Detector is maximum 8 meter. Made of stainless steel and mild steel, this plugged in charging type machine has sound and LED based alarm function. Entire structure of this equipment is rust and wear protected. Noise free function, long working life, consistent performance, zero error and standard safety features are its key aspects. Quality of this Industrial Wafer Metal Detector has been tested on the basis of its dimension, performance, user friendliness and mechanism.

Specification of Industrial Wafer Metal Detector:

FAQs of Industrial Wafer Metal Detector:

Q1: What is the reason for an industrial wafer metal detector?

A1: The basic role of an industrial wafer metal detector is to guarantee the wellbeing and nature of food items by identifying and dismissing metal impurities, like little bits of metal, metal parts, or unfamiliar articles, during the creation interaction.

Q2: How does an industrial wafer metal detector work?

A2: These metal detectors work on the standard of electromagnetic enlistment. They radiate an electromagnetic field and dissect the signs got from the item as it goes through the field. In the event that metal pollutants are available, they upset the field, setting off a caution and a dismissal system to eliminate the sullied item from the creation line.

Q3: What kinds of metal foreign substances could an industrial wafer metal detector at any point recognize?

A3: Industrial wafer metal detectors are equipped for identifying a great many metal toxins, including ferrous metals (iron and steel), non-ferrous metals (copper, aluminum, and so on), and tempered steel. They can distinguish both attractive and non-attractive metals.

Q4: Are these detectors delicate to the size of metal foreign substances?

A4: Indeed, the responsiveness of industrial wafer metal detectors can be changed in accordance with recognize metal foreign substances of various sizes. They can be arranged to meet explicit item prerequisites and security guidelines.

Q5: Might they at any point distinguish foreign substances inside the bundling of wafers or different items?

A5: Industrial wafer metal detectors are fundamentally intended to recognize metal impurities inside the actual item, not inside the bundling. Notwithstanding, a few high level frameworks can identify metal pollutants in the item's bundling, contingent upon the bundling material and thickness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

DAS ELECTRONICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |